When it comes to building efficient spray paint booths, everyone is looking for the best approach to get the job done as effectively as possible.

However, sprays have been made that not only help a product last longer, but enhance the surface the spray is used on. With this being said, here’s a look at thermal spray and how it benefits surfaces.

What’s Thermal Spray?

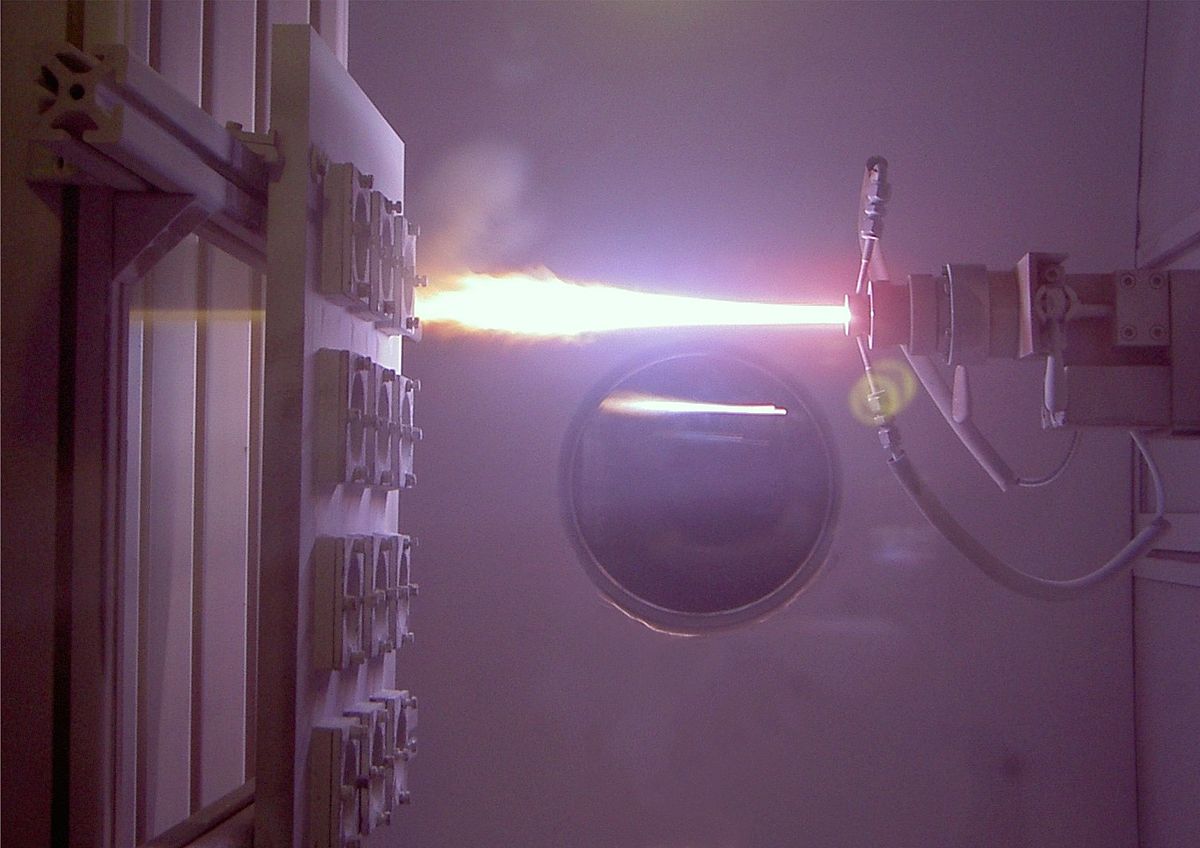

Thermal spray is the process of heating or melting products onto a surface to provide additional coating. As spray is applied by chemical or electrical means, it can be layered up to 20 micrometers and beyond – depending on what’s being applied.

In comparison to chemical vapor deposition, physical, or electroplating coating processes, thermal spraying allows a high deposition rate over a large area. The types of coating materials range from:

- Composites

- Ceramics

- Plastics

- Alloys

- Metals

With these examples only being a few of the materials used, it does help one visualize how different materials can enhance the surface it’s applied to.

Thermal spraying is applied by wire or powder form, with the compounds being heated until it’s melted – or semi-melted – and then accelerated towards the object in micro-meter particles.

The acceleration comes from the electrical arch – or combustion – which is used to apply the compound. What makes this method exceptionally efficient is the fact that it allows thermal spraying to objects that are flammable, so that the materials inside have more protection from potential outside dangers.

About Coating Qualities

The coating qualities vary depending on the compound being used and the layers of coats applied. The coating quality is measured by different characteristics such as:

With the quality of the coating increasing as the particle velocity increases, it puts into context what’s needed for an effective thermal spray. However, there’s several different methods of thermal spraying such as:

- Cold spraying

- Warm spraying

- High velocity oxy-fuel coating spraying (HVOF)

- Wire arc spraying

- Flame spraying

- Detonation spraying

- Plasma spraying

How Thermal Spray Makes Metal Better

With thermal spraying being used for a number of reasons, here’s a few reasons as to why it makes such a great choice to coat metals in a spray paint booth:

- Resisting Corrosion & Wear – A small application can extend a metal’s lifespan due to the application of thermal spray. It not only reduces corrosion, but for high-stress metal operations a coat of thermal spray can give parts an additional 200 to 1,000 hours of functional operation.

- Layer of “Skin” – Thermal spraying gives a metal product a layer of skin, resulting in less complications as the metal performs its task.

Many thermal spray paint booths assist companies that focus in gas, agricultural and oil equipment, as well as surgical and motorcycle instruments.

Working with food providers as well, the food industry uses thermal spraying to eliminate the chance of food contamination due to parts operating for product creation/distribution.

- Allows Machinery To Go Further – The best thing that thermal sprays offer for products is the fact that a coat allows the mechanism to go further than possible without protection.

Since steel can only be hardened to a certain level, a coat can help the part reach another level with wear resistance and long term use.

With the information above, thermal spraying brings out the best that metal has to offer in terms of longevity and protection.

With a simple coat adding more time to a product’s efficiency, thermal spraying is the route to pursue for getting your dollars worth from a product. It is little things like this that will determine the long term success of a business, so be sure to see if thermal spray is a process that could give you the edge over your competition.